Brand Valteс

The VALTEUS trademark appeared on the Russian market in 2003. Today, several factories in Italy, Russia, Turkey and China are engaged in the production of this brand. All VALTE products meet modern safety requirements and have good performance characteristics. Until 2015, the products had a warranty period of 7 years. In January 2015, the gradual transition to a 10-year warranty began. Some product groups will receive a guarantee of up to 15 years. VALTEC products are insured.

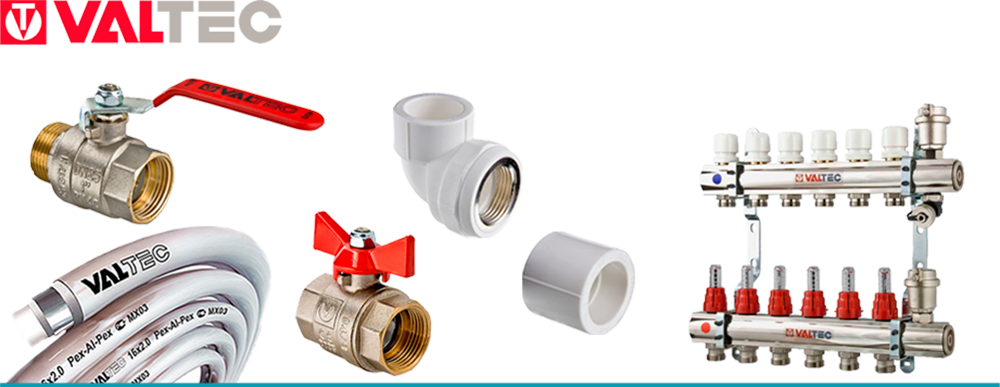

To date, the range of this brand includes:

- ~ polypropylene pipes and fittings

- ~ plastic pipes and fittings

- ~ brass threaded fittings

- ~ collectors for heating and Underfloor heating systems

- ~ brass ball valves

- ~ temperature control valves

Polypropylene pipes and fittings valte.

VALTEC offers single-layer polypropylene pipes with an outer diameter of up to 90mm. Polypropylene pipes VALTEC PP-FIBER with a multi-layer structure, reinforced with glass fiber, PP-ALUX-a solid aluminum layer that completely eliminates the diffusion of oxygen. The diameter range is from 20 to 63mm. Pipes are delivered in 4 and 2 m lengths.

Metal-plastic pipes and fittings valte.

The advantages of metal-plastic pipes are the absence of corrosion, resistance to overgrowth, the impact of aggressive building mixes, strength, smooth inner surface, convenient transportation, technological, economical installation, impermeability to gas molecules, relatively small thermal linear elongation. VALTEC pipes are used for installation of water supply systems, heating, cooling of buildings, transportation of various technological media, including food. Crosslinking of polyethylene pipes is made by organosilanide method (PEX-b). The inner (working) layer has a cross-linking degree of 65 %, the outer (protective) layer of PEX has a cross-linking degree of 55 %. This solution makes the pipe more flexible. The metal layer is butt-welded from pure aluminum foil with a thickness of 0.25-0.4 mm (for different sizes). The aluminum of the middle layer is welded by the TIG method, while the strength of the weld exceeds the strength of the aluminum layer itself. The strength of the adhesive connection of the layers is 70 N / 10 mm, with a standard of 50 N /10 mm. Repeated changes in temperature will not cause delamination of the polymer. Metal-plastic pipes VALTEC PEX-AL-PEX can be used in radiator heating (5th class of operation, GOST 32415-2013). Compliance with the passport operating conditions guarantees a 50-year service life of the product. The warranty period for VALTEC PEX-AL-PEX pipes is 10 years.

The range of offered fittings provides installation of metal-plastic and PEX pipes in the size of 16x2, 0, 20X2, 0, 26x3, 0, 32x3, 0, 40x3, 5 mm. The products are designed for systems with an operating temperature not higher than 115 °C; the nominal pressure is 25 bar. Brass threaded fittings.

The range of threaded fittings VALTE allows you to solve the problems of connecting pipelines and connecting elements in water supply, heating and other installations with a non-aggressive working environment in relation to the materials of fittings. The VALTEUS brand offers a wide range of threaded fittings for creating and commissioning new pipelines, as well as fittings for repairing existing ones.

Connectors are produced by hot stamping from CW617N (EN12165) brass, Nickel-plated (except for the chrome extension VTr.198C). For ease of installation, the external thread of the connectors is provided with notches that hold the sealing material.

Collector systems for heating and Underfloor heating valte.

The VALTEC range contains collectors/collector units of various equipment, a wide range of components.

VALTEC water collectors are widely used in heating, water supply, compressed air pipelines, and other non-aggressive liquids and gases.

Brass collectors are manufactured by volumetric hot stamping followed by Nickel plating. The metal grade is CW617N (standard EN12165). The body material of steel collectors is AISI 304 stainless steel. Seals of EPDM. The range includes collectors equipped with built-in devices-regulating fans, shut-off valves.

A set of components allows you to attach polymer, metal-plastic, steel, and copper pipes to products. Valtec floor heating manifolds are made of high-quality sanitary brass CW617N with Nickel coating or stainless steel. The collector blocks assembled on their basis are equipped with the necessary elements of binding – shut-off, tuning valves, automatic air vents, drainage taps. The seal is made with EPDM rings, no additional sealing is required. The standard for connecting pipe loops is "euroconus".

Brass ball valves.

The VALTE brand consists of four series of brass ball valves, a wide range of valves, filters and check valves.

The BASE series of ball valves are full-bore valves with an increased service life (up to 55,000 opening/closing cycles. Operating temperature range: -30... +150 °C. Nominal pressure-40-16 bar (depends on the size). Maintainable. Ball valves of the PERFECT series are full - bore, maintainable, with an increased service life (the average full service life is 55 thousand cycles; the average full service life is 30 years). Cranes are distinguished by a reinforced, massive body with an increased length of the connecting thread. This provides increased strength of the valve: PERFECT series cranes are recommended for use in cases where mechanical stresses can be transferred to the crane body due to mismatch of the axes or temperature deformations of the attached pipelines. Teflon seat rings and an oil seal in the construction of cranes allow them to be used in heating systems with operating temperatures up to 150 ° C.

Lightweight VALTEC COMPACT series. The cranes have a standard passageway, and are not repairable. Operating temperature range: -20 to + 120 °C. Rated pressure 25 bar. The average total resource is 4 thousand cycles.

The fourth series-gas valves VALGAS-are allowed to use at a temperature of -15... +60 °C (pressure-up to 3 bar). The maximum temperature of the liquid working medium is + 130 °C; the nominal pressure is 40 bar. The resource of cranes (average full) – 12 thousand cycles.