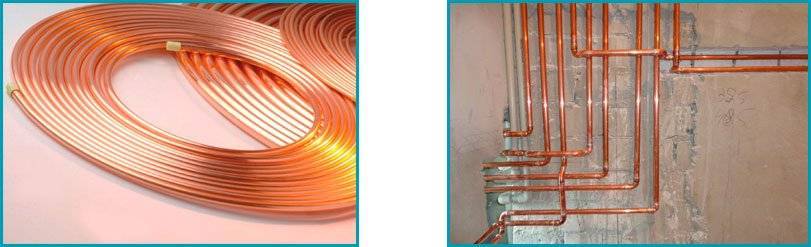

Copper pipeline

Copper pipelines have been used for a long time, but continue to compete with systems made of other materials (plastic, metal-plastic). Many technical characteristics of copper pipelines are significantly superior to all others. High strength allows a small pipe with a wall thickness of 1 mm, having a diameter of only 12 mm, to withstand a pressure of 100 bar, and the maximum allowable temperature is 250C.

Copper pipelines have been used for a long time, but continue to compete with systems made of other materials (plastic, metal-plastic). Many technical characteristics of copper pipelines are significantly superior to all others. High strength allows a small pipe with a wall thickness of 1 mm, having a diameter of only 12 mm, to withstand a pressure of 100 bar, and the maximum allowable temperature is 250C.

Using copper pipes and fittings for laying systems, you can be sure that they will not change their original characteristics for many years. One of the main advantages of such pipelines is their versatility. This allows them to be used for many purposes (heating, water supply, cold and hot). This means that the installation production system and the installation technology will be the same for these systems.

Using copper pipes and fittings for laying systems, you can be sure that they will not change their original characteristics for many years. One of the main advantages of such pipelines is their versatility. This allows them to be used for many purposes (heating, water supply, cold and hot). This means that the installation production system and the installation technology will be the same for these systems.

These pipes are easy to work with and are handled with simple tools. Connections are made using soldering, using crimping and crimping, for which various fittings are provided.

Using special fittings of various configurations with ready-to-install sockets for working with copper pipes increases the cost of the created structure, but it significantly simplifies installation and reduces the time for laying.

Even more capable of speeding up installation work fittings that have a solder fused inside. Their appearance almost does not differ from the usual socket soldering fittings. The difference is only a thin belt, squeezed out on the outer surface of the bell. Inside this belt there is a solder, it is filled in at the manufacturing stage. During installation, the solder is heated, it melts and when it spreads over the inner surface of the socket, there is a strong soldering of the connected pipes.

There is another method of connecting pipes, based on the use of brass crimp fittings. The method is based on the ability of soft metal to be easily deformed under pressure. The copper thus takes the size and shape of the body to which it is tightly pressed.

Inside this fitting is a crimping ring that ensures tightness of the connection. This ring must be tightened firmly with a connecting nut, spanner, or manually. This installation technology is necessary for installation in areas of high fire hazard, provided that the connection can be thoroughly checked for tightness. This type of fitting is used to create split pipe connections. They have slightly lower values of the sustained maximum pressure, must be regularly tightened and tested for tightness.

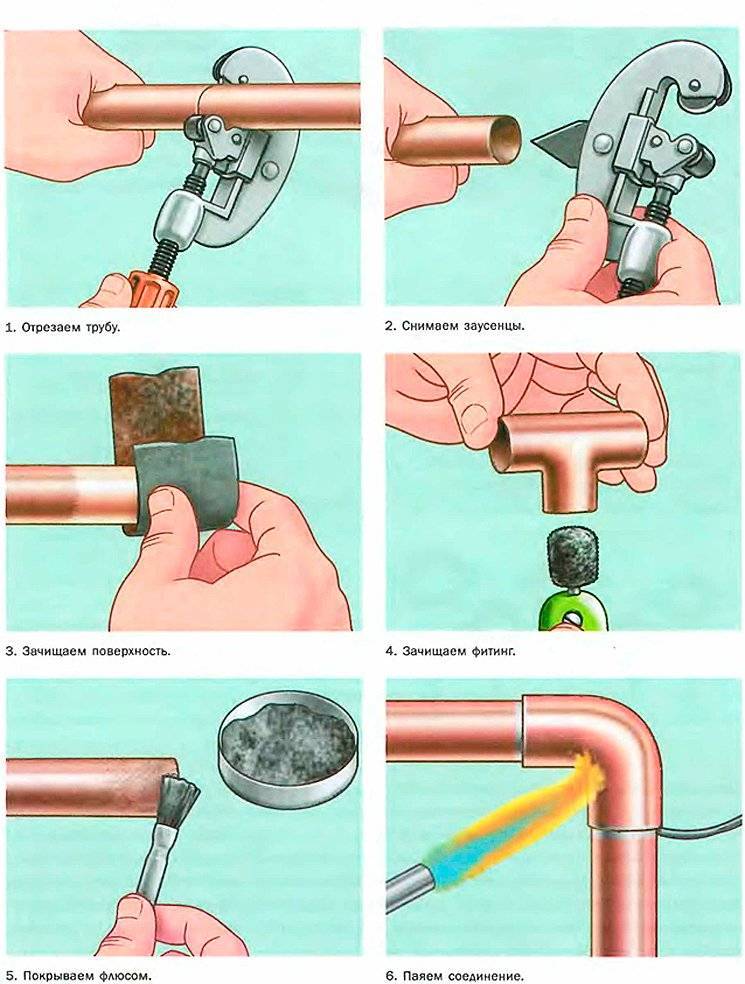

Work related to cutting copper pipes is performed on special equipment that allows you to get a smooth edge of the cut, strictly perpendicular to the axis. The end of the pipe that is crushed during cutting or installation is straightened using a special mandrel so that the pipe has the correct shape. Softer and more elastic annealed copper pipes can be bent using a special device-a pipe bend. When bending on it, the internal section of the pipe will not suffer, it will remain the correct shape.

To mount a pipeline of copper pipes and fittings at home yourself, you can use a special burner that works from a propane canister. Everyone can get a strong pipe connection if a few simple operations are performed correctly:

- When cleaning the ends of pipes and the socket, do not touch the soldering areas to avoid the appearance of greasy spots from hands;

- the flux must be applied only to the part of the pipe that will directly enter the socket or fitting;

- to prevent foreign objects from getting on the flux, the parts must be connected as quickly as possible when applying the flux;

- at the moment of joining the parts, it is necessary to turn the pipe to the position until it reaches the stop, the flux must be distributed throughout the gap;

- the connection point is heated with a heating pad to such an extent that the solder pressed to the surface of the socket melts and completely flows into the gap;

- continue heating the connection point, tightly pressing the solder to the gap, wrap it around the connected pipe;

- to determine the consumption of solder required for a single connection, you need to bend the rod in the shape of the letter G, you need to choose the length of the bend so that it is slightly longer than the diameter of the socket. The rate of consumption will be considered the length of the bent end, fused into the gap.

Copper pipelines have a number of advantages. The material of the pipes delays the penetration of oxygen, which is an important condition for the operation of heating systems. Chlorine present in the water does not destroy the walls, on the contrary, it forms a thin, very strong layer of platinum over time, protecting them, significantly extending their service life. Copper is famous for its antibacterial properties, so it suppresses pathogens in water. Copper is not threatened by the negative effects of UV rays. The almost perfectly smooth surface of the internal walls allows the use of pipes with a smaller internal diameter.