Metal-plastic pipeline

Experts give a high rating to pipelines made of metal-plastic pipes. They are widely used in the device of internal heating and Sewerage systems, all types of water supply in residential buildings. The popularity of products is due to high consumer qualities: a long service life with a guarantee of up to 50 years, strength, resistance to chemical influences, good sound insulation. These pipes are not afraid of rust and corrosion, do not impair water quality, and can withstand pressure up to 10 atmospheres. Products are delivered in convenient coils or coils, if necessary, you can purchase straight sections of the desired length.

Experts give a high rating to pipelines made of metal-plastic pipes. They are widely used in the device of internal heating and Sewerage systems, all types of water supply in residential buildings. The popularity of products is due to high consumer qualities: a long service life with a guarantee of up to 50 years, strength, resistance to chemical influences, good sound insulation. These pipes are not afraid of rust and corrosion, do not impair water quality, and can withstand pressure up to 10 atmospheres. Products are delivered in convenient coils or coils, if necessary, you can purchase straight sections of the desired length.

In order to make the right choice, it is useful to listen to the advice of experts:

1. it is Necessary to carefully inspect the offered product, special attention should be paid to the integrity of the walls. In good pipes, they are uniform, without the slightest stratification – this is a sign of high-quality material.

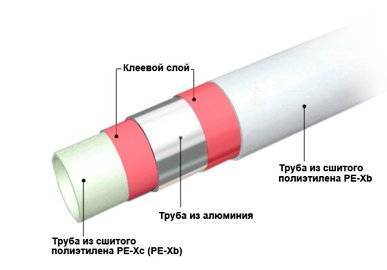

2. no less important is the thickness of the reinforcing layer of aluminum. If it is thinner than 0.3 mm, it will not provide the necessary strength and may deform when bending. If the thickness exceeds 0.55 mm, there is excessive rigidity, flexibility is lost, and installation becomes more difficult. When choosing, you need to focus on the optimal range.

3. the Inner and outer surface of high-quality pipes is made of PE-RT polymer, resistant to external influences, or cross-linked polyethylene of the REX brand. It does not lose its shape and does not soften at high temperature. Cheaper products made of HDPE (low-pressure polyethylene) are inferior in a number of parameters, including environmental safety. This is one of the reasons why pipes NORE, RE, PEHD, PE-RS are not recommended for use in everyday life.

4. Pay attention to the method of joining the metal. It is better to buy those products that are fastened butt-to-butt, and not overlap.

Detailed technical information about the materials used and the properties of the pipes can be found in the certificates, as well as by carefully examining the marking. Numerous advantages of metal plastic pipes have made them popular with customers:

Detailed technical information about the materials used and the properties of the pipes can be found in the certificates, as well as by carefully examining the marking. Numerous advantages of metal plastic pipes have made them popular with customers:

• they are characterized by ease and flexibility, the ability to maintain a given shape, and they are convenient to work with;

• low thermal conductivity reduces heat loss and condensation;

* consumers are attracted by the ease of installation – there is no need for careful size adjustment and complex equipment;

• the use of various fittings greatly facilitates the pipeline Assembly process;

• no need for continuous monitoring and maintenance of the system;

* the strength of the material guarantees long-term reliability of structures even with hidden laying.

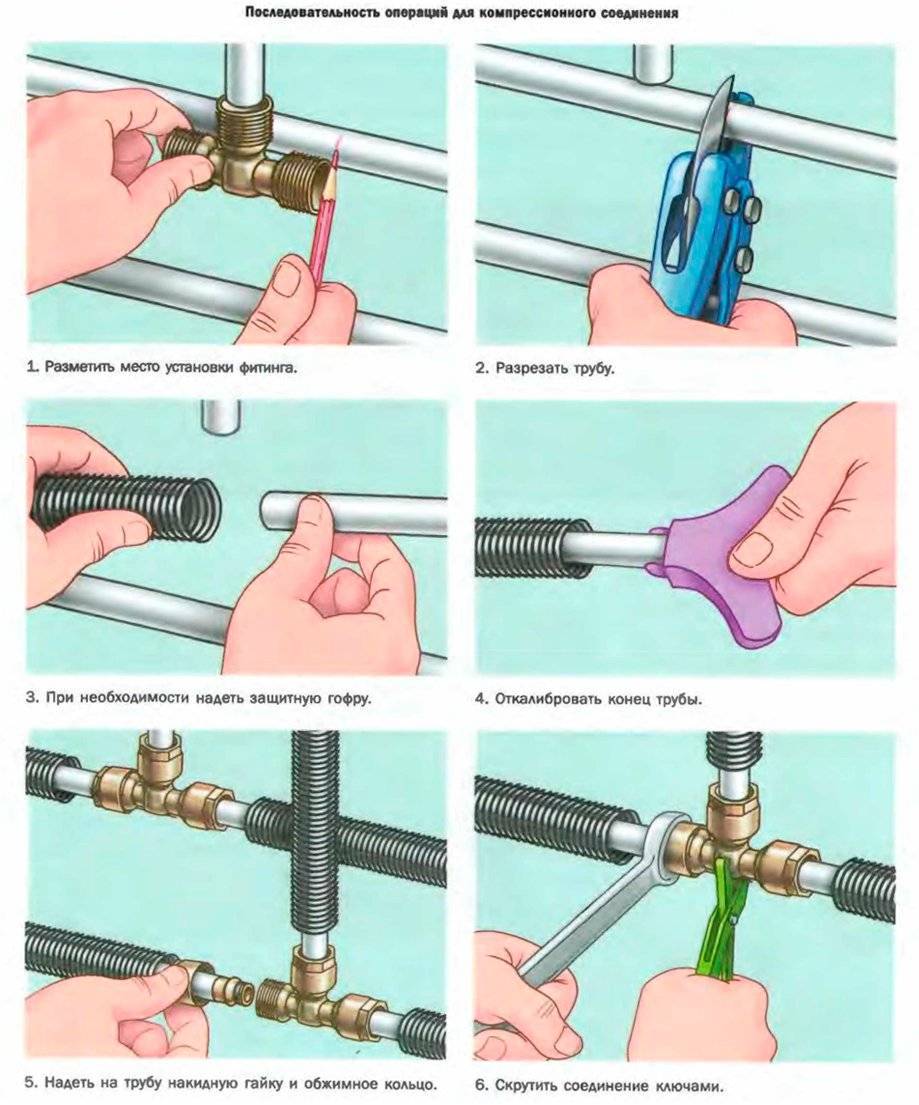

All kinds of screw fittings allow you to use them for any, even non-standard solutions. Installation is quite simple, it is available not only to specialists. It will require wrenches, pipe shears, and a calibrator.

The procedure for compression mounting is as follows:

1. Determine the location of fittings, apply markings.

2. Make incisions.

3. To calibrate all.

4. The pipe fits over the nut with an open crimp end.

5. the Connection is tightened using a key.

This simple operation does not require special knowledge and skills.

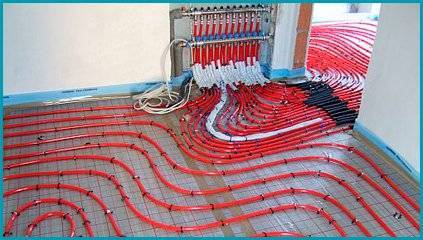

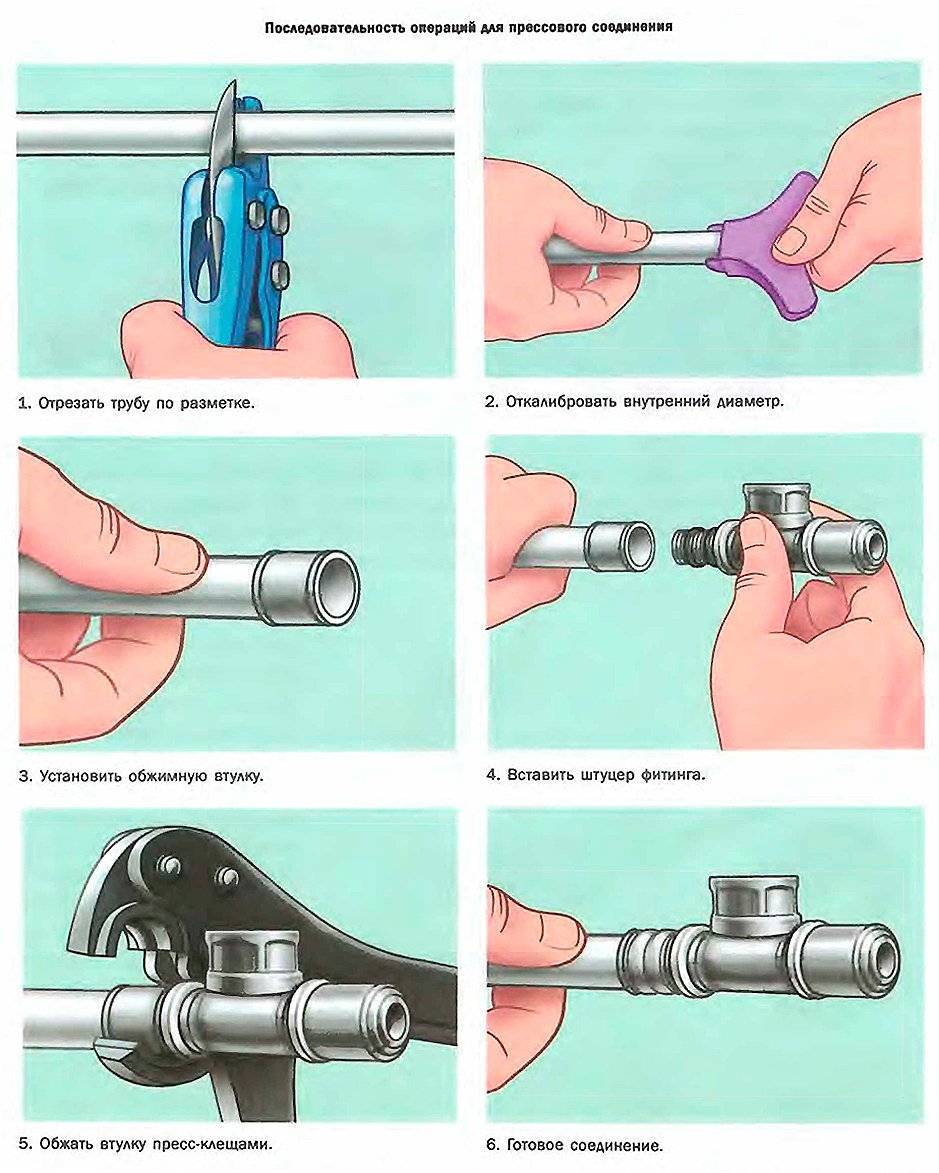

In cases where hidden pipe laying in walls or floors is necessary, it is recommended to use pressure fittings. All-in-one connections made with them are reliable and durable. They do not require preventive inspections and regulation, and can last at least 50 years. Installation of a simple pipeline can be performed even by a novice, it is better to entrust a complex configuration to a specialist.

The sequence of actions should be as follows:

1. Measure the desired length of the pipe, make a marking.

2. Cut the pipe with scissors in the intended places.

3. Perform a calibration of the diameter.

4. after installing the crimp sleeve, insert the press fitting fitting.

5. Using press-pliers, compress the bushing.

They are of two types: hydraulic or mechanical, based on a manual drive. The latter option is cheaper and easier to use, so it is often used for self-installation in everyday life. The mechanical pliers are equipped with removable inserts for pipes of different diameters and a universal crimping head. But working with them requires considerable physical strength. They are not very convenient to use in places that are difficult to access, this should be taken into account when purchasing.