Water treatment and filtration

In the modern world, the problem of clean water is becoming more and more urgent. Global environmental pollution leads to a deterioration in the quality of drinking water. Water entering the Central water supply system has an increased hardness, often it contains foreign tastes and odors. It is also likely that such water contains toxins and preservatives, which in turn are dangerous to human health.

In the modern world, the problem of clean water is becoming more and more urgent. Global environmental pollution leads to a deterioration in the quality of drinking water. Water entering the Central water supply system has an increased hardness, often it contains foreign tastes and odors. It is also likely that such water contains toxins and preservatives, which in turn are dangerous to human health.

The main sources of poor-quality drinking water can be low-efficiency treatment plants or poor water supply.

To get high-quality drinking water, any water supply system must have devices for both water purification and filtration. High-quality water prevents the formation of rust and plaque on plumbing appliances, and avoids the formation of scale in kettles, dishwashers and washing machines.

To ensure high-quality water treatment and filtration, you need to implement several stages. One of them is a chemical analysis of water, which can be done in the laboratory of sanepidnadzor, according to the analysis, the selection of elements of the water treatment system is carried out. A more accurate analysis of water from the well may be obtained only after two months of operation.

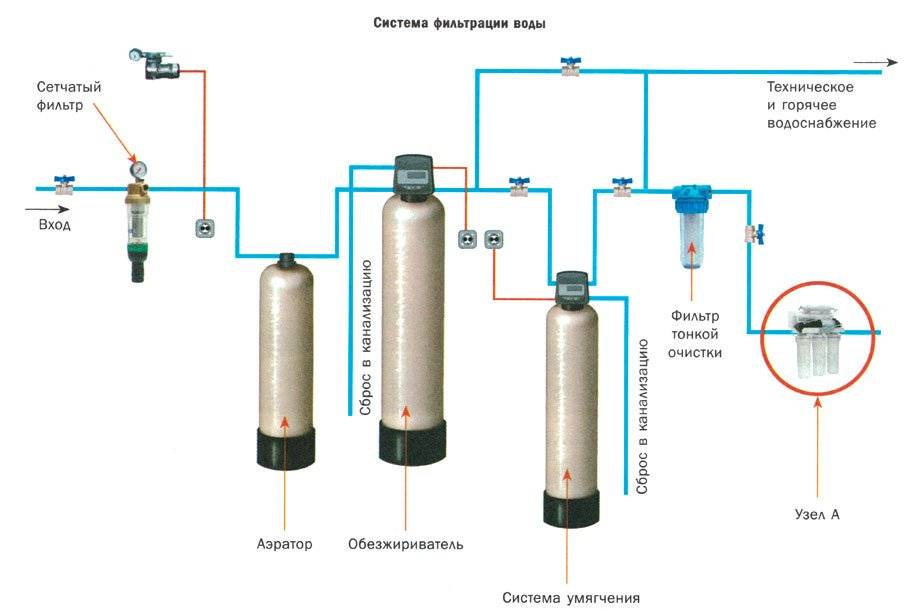

One of the components of filtration systems is a strainer designed to purify water from small suspended particles such as sand, pipe scale, etc. The active element of the filter is its replaceable cartridge, which can be washed if necessary. The cartridge is made of stainless steel, which contributes to its long-term operation.

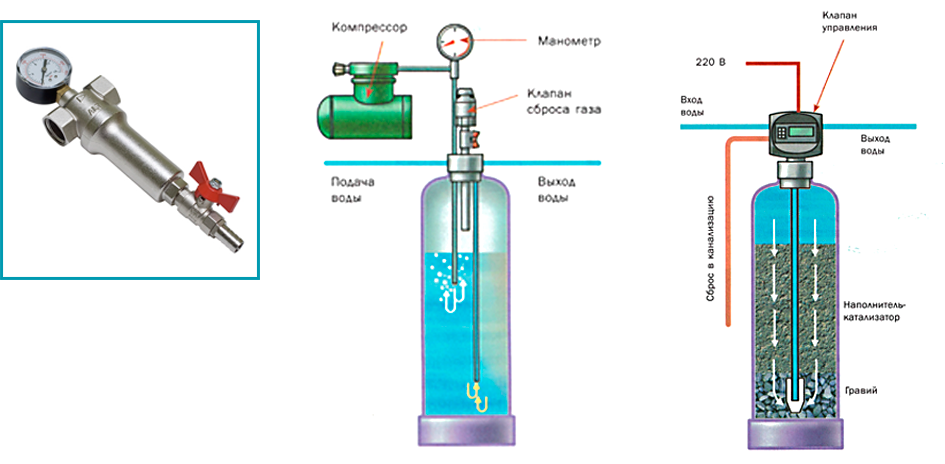

Another component of the system is the aerator. It is designed to form an air mixture that creates an air compressor, with its help, the air in the tank is pumped, saturating the water with oxygen. A special valve located on the aerator removes excess air and gases contained in the water (ammonia, hydrogen sulfide, carbon dioxide). The absorbed oxygen is intended for the oxidation of iron and organic compounds dissolved in water.

Another component of the system is the aerator. It is designed to form an air mixture that creates an air compressor, with its help, the air in the tank is pumped, saturating the water with oxygen. A special valve located on the aerator removes excess air and gases contained in the water (ammonia, hydrogen sulfide, carbon dioxide). The absorbed oxygen is intended for the oxidation of iron and organic compounds dissolved in water.

As a rule, aerators are installed together with devices that ensure the release of water from excessive iron content. The deferration filter helps to remove iron from the water, which contains a special filler, and the filter accelerates the oxidation of iron and manganese. The insoluble oxides formed during the oxidation process settle on the surface of the filler granules. Prolonged operation of the device reduces the oxidative capacity, so the device must be periodically washed. Flushing the device leads to its full recovery. For more convenient use, it is also possible to install an electronic control unit that will automatically regenerate the device, using a timer or water meter.

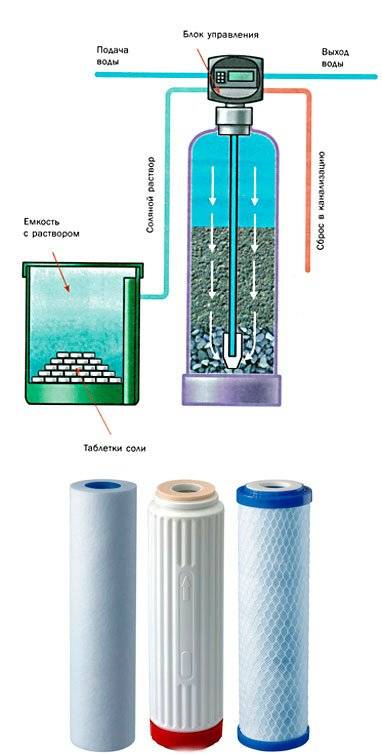

For water purification from salts of magnesium and calcium is a water softening system, it can help to prevent the formation of scale on the heating devices. The principle of operation of the device is to pass water through an ion exchange backfill, where calcium and magnesium ions are converted into harmless sodium ions. Water is delivered to the consumer via a water pipe through a filter equipped with a control valve. During long-term operation, the filter backfill must be washed in a reducing solution of table salt, which must come from the solution preparation tank. In the process of washing the filter backfill with a solution of table salt, the reverse process occurs, sodium ions are exchanged for magnesium and calcium ions located on the surface of the granules. The resulting solution is eliminated in the sewer system. It is possible to restore the filter backfill automatically using a timer or water meter. For the production of a reducing solution of table salt, a specialized salt in tablets is used.

To clean water from mechanical particles larger than 5 microns, use a fine filter equipped with a cartridge made of foamed polypropylene. Replacement of the filter element should not be performed systematically every six months, or in the case of a sudden loss of water pressure in the system.

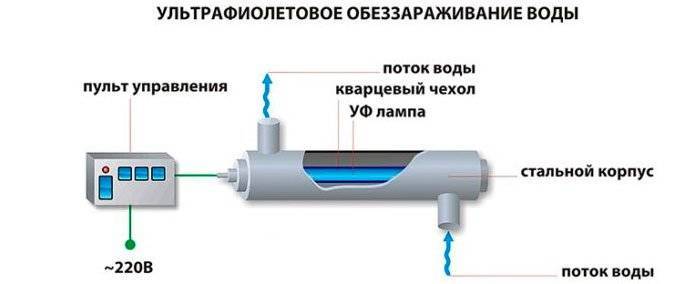

The UV unit is used to disinfect water by exposing it to ultraviolet radiation. Micro-organisms in water are exposed to ultraviolet radiation, thereby causing their structure to break down and die. During the flow of water around the UV lamp, free radicals and ozone molecules are formed, which have a high oxidizing ability, which also contribute to the destruction of microbes and bacteria. When using a lamp, no chemical or physical properties of water change, even if a high-power lamp is used. The lamp is placed in a sealed chamber made of stainless steel and protected by a special quartz shell. Over time, the device must be washed or mechanically cleaned of accumulated sediment.

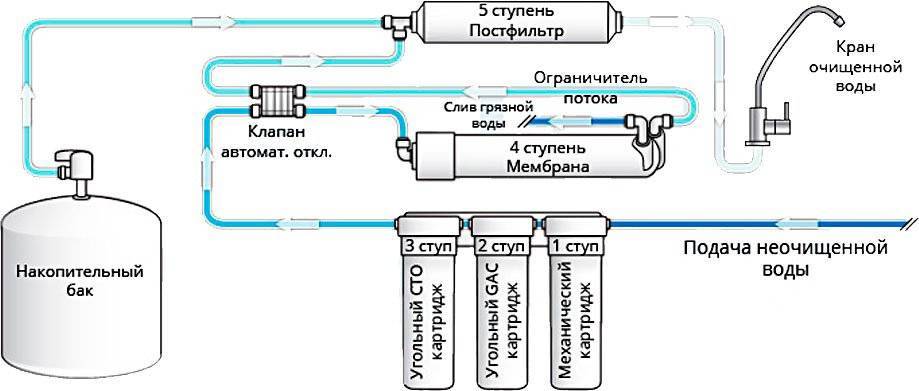

Today, there is another way to clean and filter water – a reverse osmosis installation. The installation has proven itself well in countries where water has a high content of salt, chlorine, heavy metals and other harmful elements. The principle of the device is a complex multi-stage cleaning system, which makes it possible to obtain absolutely clean water at home. In most cases, the installation consists of a pre-treatment filter, a reverse osmosis filter, and finish filters. All filters have replaceable cartridges, which in turn need to be replaced systematically.

Before water enters the reverse osmosis filters, water is usually passed through a pre-treatment filter to remove chlorine, organic and mechanical contaminants from it. This increases the service life of the reverse osmosis filter. Pre-cleaning filters include replaceable cartridges that need to be replaced in a timely manner.

Osmosis is the usual process of spreading solvent molecules through a semi-tight membrane towards a more saturated solution. Accordingly, water is a solvent for water purification. When creating excessive pressure on the water filter, reverse osmosis occurs. Which has become quite popular, recently, in the use of water purification.

The reverse osmosis filter allows you to free water from particles the size of a molecule. The filter is equipped with a semi-waterproof membrane, which allows water to pass, detains large molecules of harmful substances. Water obtained by using a reverse osmosis filter is similar in composition to distilled water, it can be consumed without pre-boiling.

For more productive operation of the reverse osmosis filter, the water pressure at the outlet should be from 2.8 to 6 ATM. So at a lower pressure, the system will need an additional pump, and at a higher pressure, the system will need to install a pressure regulator.

To improve the taste of the water consumed and saturate it with the necessary minerals, post-filters are used, which are placed after the reverse osmosis filter. Mineralizers, carbon and bioceramic filters saturate the water with the necessary components. Post-filters also have replaceable cartridges, the service life of the cartridges is no more than one year.

The main prerogative of reverse osmosis systems is their small size, which can easily be placed in small apartments. The storage barrel holds enough water for cooking, which compensates for the low performance of the system. Water supply from reverse osmosis systems is output to a separate tap on the sink.

HDPE pipe

HDPE pipe  Ball valve

Ball valve Pressure regulator

Pressure regulator Water meter

Water meter  Filter angle fine

Filter angle fine  Filter

Filter