Energoflex

The Energoflex trademark has long been famous for its quality and reliability. These products are manufactured for thermal insulation of water supply, heating, ventilation systems, as well as enclosing structures. We offer you insulation tubes of various thicknesses, thermal insulation

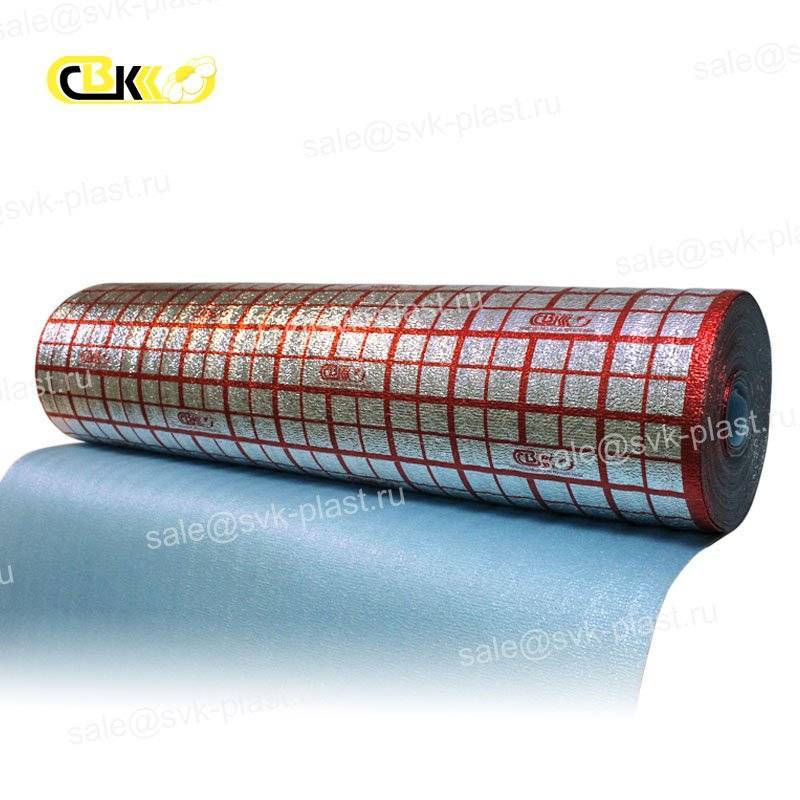

Substrate for Underfloor heating SVK

| Vendor code | Name |

|---|---|

| Подложка для теплого пола "СВК" 30м.кв х 3 мм | |

| SVK-TP-303 | Substrate for Underfloor heating "SVK" 30m. kV x 3 mm |

Energoflex Super Tube 6 mm thick

| Vendor code | Name |

|---|---|

| EFXT035062SU | Energoflex Super 35/6-2 tube |

| EFXT022062SU0 | Energoflex Super 22/6-2 tube |

| EFXT025062SU0 | Energoflex Super 25/6-2 tube |

| EFXT018062SU | Energoflex Super 18/6-2 tube |

| EFXT015062SU | Energoflex Super 15/6-2 tube |

| EFXT028062SU | Energoflex Super 28/6-2 tube |

Energoflex Super Tube 9 mm thick

| Vendor code | Name |

|---|---|

| EFXT110092SU | Energoflex Super 110/9-2 tube |

| EFXT089092SU | Energoflex Super 89/9-2 Tube |

| EFXT060092SU | Energoflex Super 60/9-2 Tube |

| EFXT076092SU | Energoflex Super 76/9-2 tube |

| EFXT035092SU | Energoflex Super 35/9-2 tube |

| EFXT022092SU | Energoflex Super 22/9-2 tube |

| EFXT064092SU | Energoflex Super 64/9-2 tube |

| EFXT054092SU | Energoflex Super 54/9-2 tube |

| EFXT133092SU | Energoflex Super 133/9-2 tube |

| EFXT160092SU | Energoflex Super 160/9-2 Tube |

| EFXT028092SU | Energoflex Super 28/9-2 tube |

| EFXT045092SU | Energoflex Super 45/9-2 tube |

| EFXT025092SU | Energoflex Super 25/9-2 tube |

| EFXT048092SU | Energoflex Super 48/9-2 tube |

| EFXT015092SU | Energoflex Super 15/9-2 tube |

| EFXT042092SU | Energoflex Super 42/9-2 tube |

| EFXT018092SU | Energoflex Super 18/9-2 tube |

| EFXT114092SU | Energoflex Super 114/9-2 tube |

Energoflex Super Tube 13 mm thick

| Vendor code | Name |

|---|---|

| EFXT048132SU | Energoflex Super 48/13-2 tube |

| EFXT015132SU | Energoflex Super 15/13-2 tube |

| EFXT018132SU | Energoflex Super 18/13-2 tube |

| EFXT042132SU | Energoflex Super 42/13-2 tube |

| EFXT110132SU | Energoflex Super 110/13-2 tube |

| EFXT022132SU | Energoflex Super 22/13-2 tube |

| EFXT076132SU | Energoflex Super 76/13-2 tube |

| EFXT028132SU | Energoflex Super 28/13-2 tube |

| EFXT025132SU | Energoflex Super 25/13-2 tube |

| EFXT045132SU | Energoflex Super 45/13-2 tube |

| EFXT114132SU | Energoflex Super 114/13-2 tube |

| EFXT160132SU | Energoflex Super 160/13-2 tube |

| EFXT133132SU | Energoflex Super 133/13-2 Tube |

| EFXT054132SU | Energoflex Super 54/13-2 tube |

| EFXT060132SU | Energoflex Super 60/13-2 tube |

| EFXT064132SU | Energoflex Super 64/13-2 tube |

| EFXT035132SU | Energoflex Super 35/13-2 tube |

| EFXT089132SU | Energoflex Super 89/13-2 Tube |

Energoflex Super Tube 20 mm thick

| Vendor code | Name |

|---|---|

| EFXT133202SU | Energoflex Super 133/20-2 Tube |

| ES14020Т | Energoflex Super 140/20-2 Tube |

| EFXT064202SU | Energoflex Super 64/20-2 Tube |

| EFXT160202SU | Energoflex Super 160/20-2 Tube |

| EFXT114202SU | Energoflex Super 114/20-2 Tube |

| EFXT025202SU | Energoflex Super 25/20-2 Tube |

| EFXT076202SU | Energoflex Super 76/20-2 Tube |

| EFXT060202SU | Energoflex Super 60/20-2 Tube |

| EFXT042202SU | Energoflex Super 42/20-2 Tube |

| EFXT022202SU | Energoflex Super 22/20-2 Tube |

| EFXT089202SU | Energoflex Super 89/20-2 Tube |

| EFXT048202SU | Energoflex Super 48/20-2 Tube |

| EFXT054202SU | Energoflex Super 54/20-2 tube |

| EFXT028202SU | Energoflex Super 28/20-2 Tube |

| EFXT045202SU | Energoflex Super 45/20-2 tube |

| EFXT110202SU | Energoflex Super 110/20-2 tube |

| EFXT035202SU | Energoflex Super 35/20-2 Tube |

Energoflex Super Tube 25 mm thick

| Vendor code | Name |

|---|---|

| EFXT035252SU | Energoflex Super 35/25-2 Tube |

| EFXT022252SU | Energoflex Super 22/25-2 tube |

| EFXT028252SU | Energoflex Super 28/25-2 Tube |

| EFXT042252SU | Energoflex Super 42/25-2 tube |

| EFXT048252SU | Energoflex Super 48/25-2 tube |

| EFXT054252SU | Energoflex Super 54/25-2 tube |

| EFXT060252SU | Energoflex Super 60/25-2 Tube |

| EFXT064252SU | Energoflex Super 64/25-2 Tube |

| EFXT076252SU | Energoflex Super 76/25-2 Tube |

| EFXT089252SU | Energoflex Super 89/25-2 Tube |

| EFXT110252SU | Energoflex Super 110/25-2 tube |

| EFXT114252SU | Energoflex Super 114/25-2 Tube |

4 mm thick Energoflex Super Protect tubes

| Vendor code | Name |

|---|---|

| EFXT0180411SUPRK | Energoflex Super Protect K 18/4-11 Tube |

| EFXT0150411SUPRK | Energoflex Super Protect K 15/4-11 Tube |

| EFXT0220411SUPRK | Energoflex Super Protect K 22/4-11 Tube |

| EFXT0350411SUPRK | Energoflex Super Protect K 35/4-11 Tube |

| EFXT0280411SUPRK | Energoflex Super Protect K 28/4-11 Tube |

Tubes Energoflex Super Protect with a thickness of 6 mm

| Vendor code | Name |

|---|---|

| EFXT028062SUPRK-240 | Energoflex Super Protect K 28/6-2 Tube |

| EFXT022062SUPRK-320 | Energoflex Super Protect K 22/6-2 Tube |

| EFXT016062SUPRBK-400 | Трубка Energoflex Super Protect BK 16/6-2 |

| EFXT028062SUPRS-240 | Energoflex Super Protect S 28/6-2 Tube |

| EFXT020062SUPRBK-320 | Трубка Energoflex Super Protect BK 20/6-2 |

| EFXT016092SUPRBK-284 | Трубка Energoflex Super Protect BK 16/9-2 |

| EFXT020092SUPRBK-240 | Трубка Energoflex Super Protect BK 20/9-2 |

| EFXT018062SUPRS-400 | Energoflex Super Protect S 18/6-2 Tube |

| EFXT035062SUPRS-160 | Energoflex Super Protect S 35/6-2 Tube |

| EFXT015062SUPRK-440 | Energoflex Super Protect K 15/6-2 Tube |

| EFXT022062SUPRS-320 | Energoflex Super Protect S 22/6-2 Tube |

| EFXT035062SUPRK-160 | Energoflex Super Protect K 35/6-2 Tube |

| EFXT015062SUPRS-440 | Energoflex Super Protect S 15/6-2 Tube |

| EFXT018062SUPRK-400 | Energoflex Super Protect K 18/6-2 tube |

9 mm thick Energoflex Super Protect tubes

| Vendor code | Name |

|---|---|

| EFXT022092SUPRS-240 | Energoflex Super Protect S 22/9-2 Tube |

| EFXT015092SUPRK-356 | Energoflex Super Protect K 15/9-2 Tube |

| EFXT018092SUPRK-284 | Energoflex Super Protect K 18/9-2 tube |

| EFXT035092SUPRK-136 | Energoflex Super Protect K 35/9-2 Tube |

| EFXT032092SUPRBK-148 | Трубка Energoflex Super Protect BK 32/9-2м |

| EFXT025092SUPRBK-200 | Трубка Energoflex Super Protect BK 25/9-2м |

| EFXT042092SUPRK-110 | Трубка Energoflex Super Protect K 42/9-2 |

| EFXT042092SUPRS-110 | Трубка Energoflex Super Protect S 42/9-2 |

| EFXT028092SUPRS-168 | Energoflex Super Protect S 28/9-2 Tube |

| EFXT018092SUPRS-284 | Energoflex Super Protect S 18/9-2 Tube |

| EFXT035092SUPRS-136 | Energoflex Super Protect S 35/9-2 Tube |

| EFXT015092SUPRS-356 | Energoflex Super Protect S 15/9-2 Tube |

| EFXT028092SUPRK-168 | Energoflex Super Protect K 28/9-2 Tube |

| EFXT022092SUPRK-240 | Energoflex Super Protect K 22/9-2 Tube |

Energoflex Super SK Tube 9 mm thick

| Vendor code | Name |

|---|---|

| EFXT028092SUSK | Energoflex Super SK 28/9-2 tube |

| EFXT035092SUSK | Energoflex Super SK 35/9-2 tube |

| EFXT018092SUSK | Energoflex Super SK 18/9-2 tube |

| EFXT048092SUSK | Energoflex Super SK 48/9-2 tube |

| EFXT022092SUSK | Energoflex Super SK 22/9-2 tube |

| EFXT042092SUSK | Energoflex Super SK 42/9-2 tube |

| EFXT054092SUSK | Energoflex Super SK 54/9-2 tube |

| EFXT025092SUSK | Energoflex Super SK 25/9-2 tube |

| EFXT060092SUSK | Energoflex Super SK 60/9-2 tube |

Energoflex Super SK Tube 13 mm thick

| Vendor code | Name |

|---|---|

| EFXT054132SUSK | Energoflex Super SK 54/13-2 tube |

| EFXT042132SUSK | Energoflex Super SK 42/13-2 tube |

| EFXT018132SUSK | Energoflex Super SK 18/13-2 tube |

| EFXT022132SUSK | Energoflex Super SK 22/13-2 tube |

| EFXT025132SUSK | Energoflex Super SK 25/13-2 tube |

| EFXT028132SUSK | Energoflex Super SK 28/13-2 tube |

| EFXT035132SUSK | Energoflex Super SK 35/13-2 tube |

| EFXT060132SUSK | Energoflex Super SK 60/13-2 tube |

| EFXT089132SUSK | Energoflex Super SK 89/13-2 tube |

| EFXT042132SUSK | Energoflex Super SK 48/13-2 tube |

| EFXT076132SUSK | Energoflex Super SK 76/13-2 tube |

Energoflex Super SK 20 mm thick Tube

| Vendor code | Name |

|---|---|

| EFXT022202SUSK | Energoflex Super SK 22/20-2 tube |

| EFXT025202SUSK | Energoflex Super SK 25/20-2 tube |

| EFXT028202SUSK | Energoflex Super SK 28/20-2 tube |

| EFXT035202SUSK | Energoflex Super SK 35/20-2 tube |

| EFXT042202SUSK | Energoflex Super SK 42/20-2 tube |

| EFXT089202SUSK | Energoflex Super SK 89/20-2 tube |

| EFXT048202SUSK | Energoflex Super SK 48/20-2 tube |

| EFXT076202SUSK | Energoflex Super SK 76/20-2 tube |

| EFXT054202SUSK | Energoflex Super SK 54/20-2 tube |

| EFXT060202SUSK | Energoflex Super SK 60/20-2 tube |

| EFXT110202SUSK | Energoflex Super SK110/20-2 tube |

Energofloor Compact Rolls

| Vendor code | Name |

|---|---|

| EFRR03130COM | Energofloor COMPACT 3/1-30 roll (formerly Super TP Al) |

| EFRR05120COM | Energofloor COMPACT 5/1-20 roll (formerly Super TP Al) |

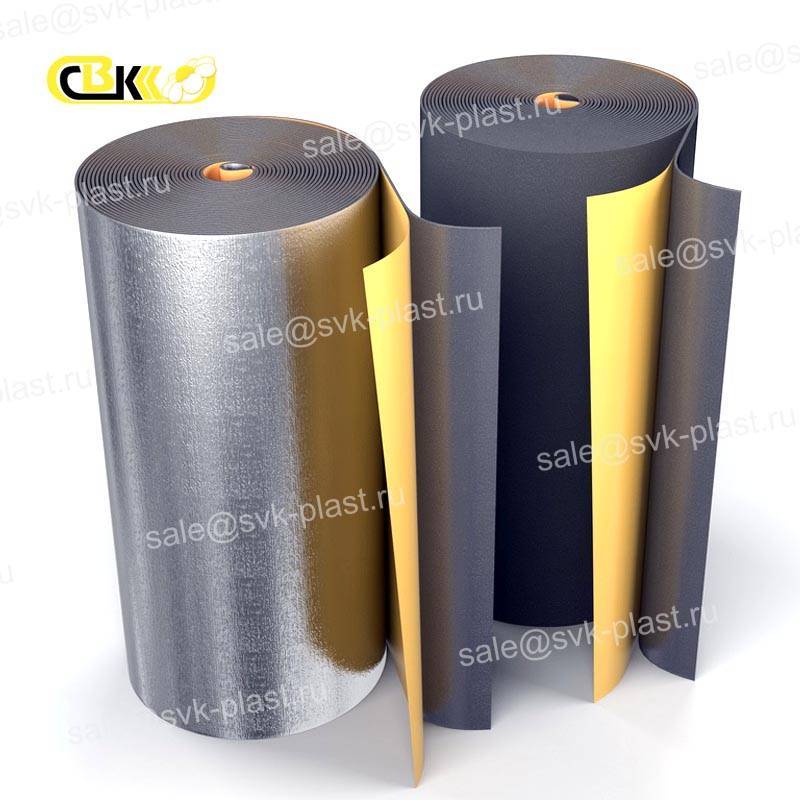

Energoflex Super AL rolls

| Vendor code | Name |

|---|---|

| EFXR1517SUAL | Energoflex Super AL Roll 15/1, 0-7 |

| EFXR2015SUAL | Energoflex Super AL Roll 20/1, 0-5 |

| EFXR05120SUAL | Energoflex Super AL Roll 5/1, 0-20 |

| EFXR10110SUAL | Energoflex Super AL Roll 10/1, 0-10 |

| EFXR03130SUAL | Energoflex Super AL Roll 3/1, 0-30 |

Energoflex Super Rolls

| Vendor code | Name |

|---|---|

| EFXR1317SU | Energoflex Super Roll 13/1, 0-7 |

| EFXR10110SU | Energoflex Super 10/1,0-10 roll |

| EFXR2015SU | Energoflex Super 20/1,0-5 roll |

9 mm thick Energocell HT tubes

| Vendor code | Name |

|---|---|

| ECLT042092HT | ENERGOCELL HT 42/9-2 tube |

| ECLT022092HT | ENERGOCELL HT 22/9-2 tube |

| ECLT048092HT | ENERGOCELL HT 48/9-2 tube |

| ECLT054092HT | ENERGOCELL HT 54/9-2 tube |

| ECLT060092HT | ENERGOCELL HT 60/9-2 tube |

| ECLT089092HT | ENERGOCELL HT 89/9-2 tube |

| ECLT028092HT | ENERGOCELL HT 28/9-2 tube |

| ECLT035092HT | ENERGOCELL HT 35/9-2 tube |

| ECLT076092HT | ENERGOCELL HT 76/9-2 tube |

13 mm thick Energocell HT tubes

| Vendor code | Name |

|---|---|

| ECLT022132HT | ENERGOCELL HT 22/13-2 tube |

| ECLT028132HT | ENERGOCELL HT 28/13-2 tube |

| ECLT035132HT | ENERGOCELL HT 35/13-2 tube |

| ECLT042132HT | ENERGOCELL HT 42/13-2 tube |

| ECLT048132HT | ENERGOCELL HT 48/13-2 tube |

| ECLT054132HT | ENERGOCELL HT 54/13-2 tube |

| ECLT060132HT | ENERGOCELL HT 60/13-2 tube |

| ECLT076132HT | ENERGOCELL HT 76/13-2 tube |

| ECLT089132HT | ENERGOCELL HT 89/13-2 tube |

| ECLT108132HT | ENERGOCELL HT108/13-2 tube |

Energocell HT tubes 19 mm thick

| Vendor code | Name |

|---|---|

| ECLT022192HT | ENERGOCELL HT 22/19-2 tube |

| ECLT028192HT | ENERGOCELL HT 28/19-2 tube |

| ECLT035192HT | ENERGOCELL HT 35/19-2 tube |

| ECLT042192HT | ENERGOCELL HT 42/19-2 tube |

| ECLT048192HT | ENERGOCELL HT 48/19-2 tube |

| ECLT054192HT | ENERGOCELL HT 54/19-2 tube |

| ECLT060192HT | ENERGOCELL HT 60/19-2 tube |

| ECLT076192HT | ENERGOCELL HT 76/19-2 tube |

| ECLT089192HT | ENERGOCELL HT 89/19-2 tube |

| ECLT108192HT | ENERGOCELL HT108/19-2 tube |

Energocell HT tubes 25 mm thick

| Vendor code | Name |

|---|---|

| ECLT035252HT | ENERGOCELL HT 35/25-2 tube |

| ECLT028252HT | ENERGOCELL HT 28/25-2 tube |

| ECLT048252HT | ENERGOCELL HT 54/25-2 tube |

| ECLT060252HT | ENERGOCELL HT 60/25-2 tube |

| ECLT089252HT | ENERGOCELL HT 89/25-2 tube |

| ECLT042252HT | ENERGOCELL HT 42/25-2 tube |

| ECLT048252HT | ENERGOCELL HT 48/25-2 tube |

| ECLT076252HT | ENERGOCELL HT 76/25-2 tube |

| ECLT108252HT | ENERGOCELL HT 108/25-2 tube |

Energocell HT rolls

| Vendor code | Name |

|---|---|

| ECLR13114HT | ENERGOCELL HT Roll 13/1. 0-14 |

| ECLR2518HT | ENERGOCELL HT 25/1.0-14 Roll |

| ECLR10120HT | ENERGOCELL HT Roll 10/1. 0-20 |

| ECLR19110HT | ENERGOCELL HT Roll 19/1. 0-14 |

Energofloor Tacker thermal insulation Mat

| Vendor code | Name |

|---|---|

| Mat Energofloor Tacker 25/1-3,5 | |

| EFRM3013/2TKR | ENERGOFLOOR TACKER mat 30/1-3,2 DES-sg |

| Energofloor Tacker Mat 30/1, 0-1. 6 DES-sg |

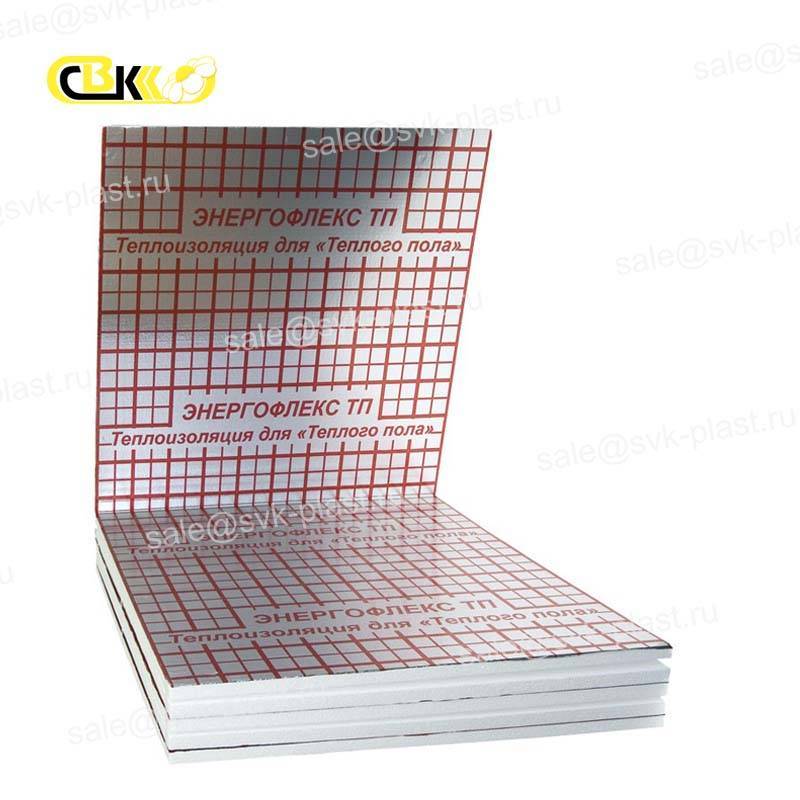

Thermal insulation plate Energofloor Tacker

| Vendor code | Name |

|---|---|

| EFRP3011/6TKR | ENERGOFLOOR TACKER 30/1-1,6 DES-sg stove |

| EFRP2010/8 | Energofloor plate 20/1. 0 - 0.8 DEO-dm |

| EFRP5010/8 | Energofloor 50/1.0 - 0.8 DEO - dm plate |

Energofloor Pipelock Plate

| Vendor code | Name |

|---|---|

| EFRP300/71/1PLK | ENERGOFLOOR PIPELOCK 30/0,7-1,1 DES-sg plate |

| EFRP0/71/1PLKSOL | ENERGOFLOOR PIPELOCK SOLO cooker 0,7-1,1 |

| EFRP200/71/1PLK | ENERGOFLOOR PIPELOCK 20/0,7-1,1 DES-sg plate |

Energofloor damping tape

| Vendor code | Name |

|---|---|

| EFRL101001DM | Energofloor 10/0,1-11 damping tape |

| EFRL1015011DM | Energofloor 10/0,15-11 damping tape |

Energoflex Super SK self-adhesive tape

| Vendor code | Name |

|---|---|

| EFXL0305015SUSK | Self-adhesive tape Energoflex Super SK 3/0, 05-15 |

| EPKL5025TKSK | Self-adhesive tape Energopak TK SK 50MM X 25M |

| ECLL0305015HTSK | Self-adhesive tape.Energocell HT 3/0.05-15 |

Energoflex self-adhesive reinforced tape

| Vendor code | Name |

|---|---|

| EFXL04810ARSKGR | Self-adhesive reinforced tape.Energoflex 48mmx10m ser. |

| EPRL04850ARSKGRR | Self-adhesive reinforced tape.Energoflex 48mmx50m ser. |

| EPRL04825ARSKBL | Self-adhesive reinforced tape.Energoflex 48mmx25m sin. |

| EPRL04825ARSKGRR | Self-adhesive reinforced tape.Energoflex 48mmx25m grey |

| ECLL04833PVCSKBK | Self-adhesive reinforced tape.Energocell PVC 48mmx33m black. |

| EPRL04825ARSKRD | Self-adhesive reinforced tape.Energoflex 48mmx25m kr. |

| EFXL04850ARSKBK | Self-adhesive reinforced tape.Energoflex 48mmx50m black |

Energoflex aluminum self-adhesive tape

| Vendor code | Name |

|---|---|

| EPRL05050ALSKC | Energoflex 50mmx50m self-adhesive aluminum tape |

Energoflex Extra Glue

| Vendor code | Name |

|---|---|

| EFXADH0/5EXT | Energoflex Extra 0.5 l glue |

| ECLADH2/6HT | Energocell® HT glue 2,6 l. |

| EPRADH0/8B | Energoflex Extra 0.8 l adhesive |

| EPRADH2/0B | Energoflex Extra glue 2.6 l |

What is polyethylene foam?

By its properties, foamed polyethylene (polyethylene foam) is not only a universal insulation, but also an excellent sound insulation material, which is widely used in construction. At the moment, there are two different types of this material - unstitched and cross-linked foamed polyethylene.

In non-crosslinked polyethylene foam, polymer molecules do not have any chemical relationship with each other, so this material has a low density and a rather loose structure. It is also easily deformed by compression, while its shape is not restored after removing the load on the material.

The structure of cross-linked polyethylene foam is characterized by the presence of small cells and high density. The material also differs in its properties - it has a fairly low thermal conductivity and low vapor permeability. Cross-linked polyethylene foam can withstand high compression pressure with minimal deformation, and it absorbs sound much better than its non-cross-linked counterpart.

Material production technology

Polyethylene pellets are poured into a special drum of the extruder, where they melt at a temperature of 115 degrees. When the pellets are melted, nitrogen or carbon dioxide is added to the resulting mass. When they are mixed by extrusion, a material with a porous structure is obtained. To make the mass of polyethylene foam uniform, the drum constantly rotates during the melting of granules.

Unstitched polyethylene foam is manufactured at a temperature of 180 degrees. To obtain a cross-linked material, it is heated to 220 degrees.

After mixing and melting, the finished mass is poured into a special mold and cooled in it.

Application

Foamed polyethylene is used:

- For arrangement of heat and sound insulation of various structures during construction.

- For finishing and insulation of car interiors, ship cabins and other vehicles.

- For insulation of doors, Windows, as well as as a substrate for some floor coverings.

- As a packaging material for transporting various electrical appliances and furniture.

- In the production of sports and tourist goods. Foam polyethylene mats are made for tourists, where you can sleep on the wet ground without fear of hypothermia.

The versatility of the material, combined with its low cost, allows you to use polyurethane foam for a variety of purposes.

Triple advantage of pipes made of polyethylene foam

Steel, copper and other types of pipes often need protection from external influences. Pipes made of foamed polyethylene perfectly cope with this task. They are based on a special porous material that reliably protects pipes made of a variety of materials from excessive moisture, heat and other negative factors that can affect the functionality of these pipes.

The scope of application of pipes made of polyethylene foam

A large part of modern communications, needs good protection. Their service life can be significantly extended if these pipes are covered with something on top. As a basis for providing protection, tubes made of foamed polyethylene are used. They reliably help both in the hot season and in winter (by the way, in winter protection is no less necessary, since pipes can burst in severe frosts). When using protective tubes made of foamed polyethylene, you can be absolutely sure. That communication will function normally for quite a long time.

Foamed polyethylene is used in many areas. But its main purpose is to protect steel, copper and other structures from the negative impact of various environmental factors. Pipes made of foamed polyethylene are equally successfully used both in the domestic sphere and in industry. Their most common use is for insulation:

- Heating system;

- Systems designed for air conditioning and ventilation systems;

- Supply system;

- Sewerage system;

- Fencing systems;

- Refrigerators and freezers.

The diameter of the tubes can reach 160 mm, and the thickness of the protective layer is usually 20 mm. These are the most optimal indicators, although others may apply. If insulation of systems with a diameter of more than 16 cm is required, polyethylene layers are used instead of tubes.

The most common pipes are made of foamed polyethylene with a length of 2 meters. They can be painted in a variety of colors. As for the installation of the tube, there are usually no problems. If the length of the tube exceeds the same indicator of the system itself, it is enough to simply cut off some of the excess protective material. In some tubes, aluminum foil is pasted on one side. Its purpose is to protect the system from ultraviolet radiation.

Advantages and disadvantages of protective structures made of foamed polyethylene

Like any material, foamed polyethylene has certain advantages and disadvantages. First, we will highlight the main advantages of polyethylene foam tubes:

- High degree of thermal insulation. Thanks to the use of protective tubes made of foamed polyethylene, it is possible to achieve temperature retention of up to 80 percent of the initial values. Thus, you can save a lot on small heat losses.

- Reliable protection of the main structure from corrosion due to the fact. that the percentage of water absorption of foamed polyethylene does not exceed 2 %.

- Thanks to the use of foamed polyethylene, it is possible to provide a good vapor barrier, since condensate will not accumulate on the main structure.

- The ability to use basic structures in non-standard weather conditions. Thanks to pipes made of foamed polyethylene, they can be operated at temperatures from minus 80 to plus 95 degrees.

- High degree of sound insulation. The use of polyethylene foam tubes almost completely absorbs noise from the main system.

- Low weight, so that the mass of the main structure remains unchanged.

- Easy to install. No special knowledge or experience is required here.

- Safe impact on the environment. No harmful substances are used in the manufacture of protective structures made of foamed polyethylene, so environmental pollution can be avoided.

- High level of durability even after several years of operation.

- The minimum service life is at least 25 years.

- Immunity to aggressive environments, as well as non-standard and dangerous chemicals.

- Disadvantages of structures made of foamed polyethylene are also available, but they are very few.

- Under the influence of an open fire, the foamed polyethylene begins to melt after about 30 minutes, which is why these protective structures are classified as combustible.

- tubes that do not have aluminum foil are not protected from UV rays, which can cause their structure to collapse.

Features of production, installation and routine maintenance of polyethylene pipes

The production process the structure made of polyethylene foam looks like this? first, polyethylene is taken and heated under the influence of high temperature. After that, a certain amount of isobutane is added to it. This results in a mixture that is at least 20 times larger than the size of the original materials used.

Installation of protective pipes made of polyethylene is not difficult. If the system is not yet assembled, then each tube must be stretched over the corresponding part of the pipe. If the system is already fully installed, then the tube should be disconnected, pulled over the structure and secured with the help of knees. When buying protective pipes, you need to pay attention to their diameter coinciding with the outer diameter of the pipe that is insulated. Choose a protective tube from this point of view can be quite easy-the benefit of a variety of materials available in each store.

As for the treatment of protective tubes when they are installed on a ready-made system, in addition to the knees, it would be nice to use glue. With its help, the seam will be sealed, and the structure itself will be as protected as possible.

Removing the insulation pipe is no more difficult than installing it. Simply disconnect the seam or cut a new one and remove the structural elements.

Based on the above, pipes made of foamed polyethylene are currently quite common protective structures that prevent the development of corrosion on copper, steel and other types of pipes, as well as ensure their proper level of waterproofing and other operating parameters.